Optical Fibre Diameter Analyser: A Key Tool for Precision in Fibre Optic Cable Manufacturing

Optical Fibre Diameter Analyser: A Key Tool for Precision in Fibre Optic Cable Manufacturing

Blog Article

Exactly How an Optical Fibre Diameter Analyser Improves Quality Assurance in Fibre Production

The assimilation of an Optical Fibre Diameter Analyser right into Fibre production procedures stands for a substantial development in quality control methods. By supplying real-time, accurate measurements of Fibre sizes, this technology resolves the essential need for consistency in manufacturing criteria.

Importance of Fibre Diameter Measurement

Precise measurement of Fibre Diameter is essential in the field of optical Fibre modern technology, as it straight affects the efficiency and integrity of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capability, attenuation, and overall transmission efficiency. Accuracy in gauging Fibre Diameter makes sure that the optical buildings are kept within defined tolerances, which is important for optimal signal integrity.

Variants in Fibre Diameter can result in enhanced losses due to spreading and modal diffusion, affecting the quality of data transmission. In high-speed interaction systems, such inconsistencies can lead to significant destruction of signal top quality, causing data errors and lowered performance. Furthermore, consistent Fibre Diameter is crucial for compatibility with ports and splicing technologies, which are integral parts of Fibre optic networks.

Quality assurance procedures in Fibre production greatly depend on accurate Diameter measurements to make sure compliance with sector requirements. By implementing durable measurement methods, manufacturers can improve product dependability, minimize waste, and enhance overall system efficiency. Hence, the relevance of Fibre Diameter dimension can not be overemphasized, as it works as a foundation in the advancement of optical Fibre technology and its applications in contemporary interaction networks.

How the Analyser Functions

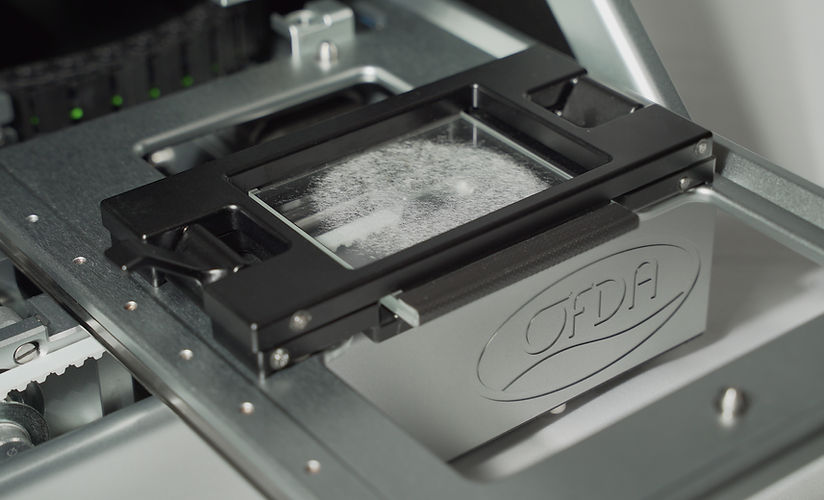

The reliable dimension of Fibre Diameter relies upon sophisticated logical techniques that make sure accuracy and reliability in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a combination of laser modern technology and progressed picture handling formulas to accurately analyze the Diameter of fibres as they are created

Originally, a laser beam is directed at the moving Fibre, developing a cross-sectional darkness. The analyser catches this darkness using high-resolution video cameras placed purposefully along the production line. The captured images are then processed in real-time to establish the Fibre's Diameter with remarkable accuracy.

The system uses innovative formulas that make up various aspects, consisting of variations in light intensity and environmental conditions, to improve measurement dependability. It can find minute adjustments in Diameter, such as variations that could take place during the production procedure.

In addition, the analyser can taking care of numerous fibers concurrently, boosting throughput without jeopardizing accuracy. By giving instantaneous responses on the Diameter, the Optical Fibre Diameter Analyser plays an essential role in keeping rigid quality assurance standards, ensuring that the end product satisfies industry specifications and consumer demands.

Advantages of Real-Time Surveillance

While conventional methods of monitoring Fibre Diameter typically entail taxing post-production checks, real-time tracking considerably enhances the effectiveness and quality of optical Fibre manufacturing. optical fibre diameter analyser. This positive approach permits producers to recognize variances in Fibre Diameter as they take place, rather than waiting till production is full to examine high quality

By continually determining the Diameter during manufacturing, manufacturers can make sure that the fibers satisfy rigorous specs, bring about lowered variability and boosted consistency. Real-time tracking additionally enables instant corrective actions to be taken, lessening waste and avoiding faulty fibres from getting in the supply chain.

Additionally, this innovation promotes enhanced data collection and evaluation, giving insights into manufacturing fads and prospective areas for renovation. Such data-driven decision-making equips manufacturers to optimize processes and preserve high criteria of quality control.

Furthermore, real-time tracking promotes a society of continuous improvement within the production atmosphere. Workers are extra involved when they can see the impact of their operate in real-time, resulting in increased responsibility and a dedication to quality. On the whole, the application of real-time surveillance systems in optical Fibre production converts to superior product quality and increased customer complete satisfaction.

Effect On Production Effectiveness

Applying optical Fibre Diameter analysers dramatically boosts manufacturing effectiveness by enhancing the manufacturing my latest blog post process. These devices facilitate continuous surveillance of Fibre Diameter, enabling producers to spot discrepancies in real-time. By identifying inconsistencies without delay, manufacturing lines can be changed rapidly, reducing downtime and reducing the chance of producing defective products.

Furthermore, the assimilation of these analysers right into the production workflow makes it possible for better source allotment. With precise Diameter dimensions, operators can maximize material use, making certain that resources find out are not wasted on flawed fibers. This precision additionally adds to less revamp and scrap, inevitably reducing production expenses.

The automation offered by optical Fibre Diameter analysers reduces reliance on hand-operated assessments, which are vulnerable and typically taxing to human error. Because of this, staff members can concentrate on more tactical jobs, enhancing general performance.

Furthermore, the information generated from these analysers can educate process enhancements and facilitate far better decision-making. By analyzing patterns in Fibre Diameter variations, suppliers can execute aggressive measures to improve manufacturing techniques and maintain constant top quality. In summary, optical Fibre Diameter analysers play a crucial duty in boosting production effectiveness, bring about better outcome and boosted productivity.

Case Research Studies and Success Stories

Throughout numerous industries, situation research studies highlight the transformative influence of optical Fibre Diameter analysers on manufacturing procedures. One noticeable example is a leading telecommunications company that faced challenges with inconsistent Fibre diameters, resulting in boosted being rejected prices. By incorporating an optical Fibre Diameter analyser, the business accomplished real-time tracking of Fibre measurements, leading to a 30% decrease in flaws and considerable expense financial savings.

In addition, a research study institution read what he said concentrating on sophisticated products used optical Fibre Diameter analysers to improve their experimental processes. The analyser's capability to supply comprehensive understandings into Fibre consistency allowed the development of ingenious materials with enhanced efficiency qualities.

These success tales underscore the crucial duty of optical Fibre Diameter analysers in boosting quality assurance, enhancing manufacturing effectiveness, and driving technology across varied sectors.

Conclusion

In conclusion, the Optical Fibre Diameter Analyser plays a pivotal role in enhancing top quality control within Fibre manufacturing. As shown with various instance researches, the analyser shows vital for accomplishing premium item top quality in Fibre manufacturing.

The execution of optical Fibre Diameter analysers allowed for rigorous high quality control, guaranteeing that the generated fibres fulfilled exacting market criteria.In final thought, the Optical Fibre Diameter Analyser plays an essential role in improving quality control within Fibre manufacturing.

Report this page